ALL Gloves

Editorial | 09 August 2021

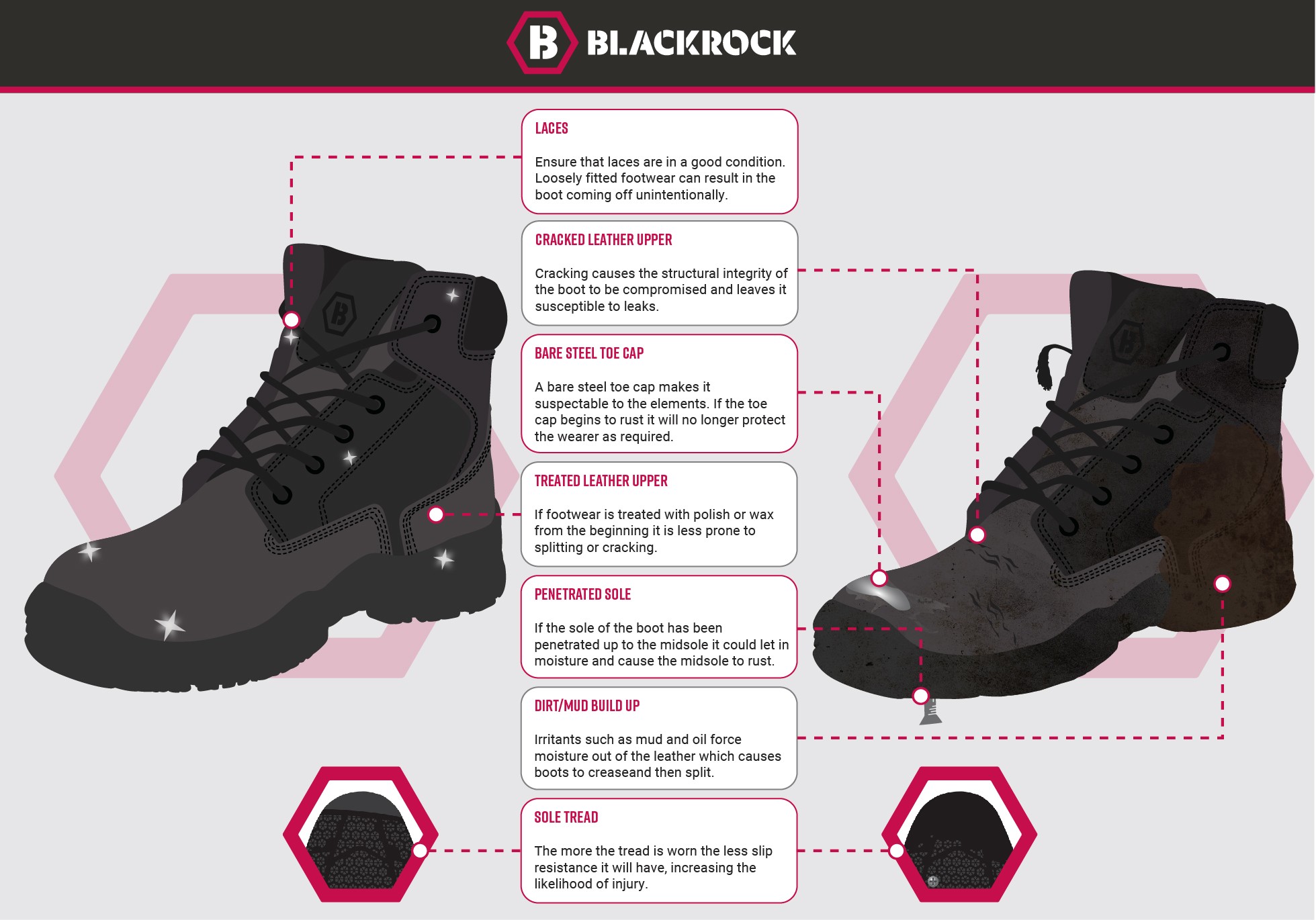

Just like the tyres on your car, work boots have a lifespan. After a certain amount of use work boots will no longer be able to perform to the standard that is required.

Key safety areas include the toe cap, the sole tread and the protective midsole. Midsoles and toe caps come in two different forms: the traditional steel toe cap and midsole, or the more modern non-metallic (composite) style. Both forms provide the same level of protection for the wearer (200J) however composite styles tend to be lighter.

Not everyone has time to care for their work boots after a shift as there is always somewhere we would rather be, whether it’s in the pub or at home for tea. In this article we aim to raise awareness of steps that can be taken to prevent a workplace accident by identifying damaged footwear.

Certain defects are easy to spot. For example, if a steel toe cap is deformed or uncovered the footwear should be taken out of service. However, just because there is no damage visible doesn’t mean the boot is structurally sound; if a heavy load has been dropped on a steel toe there could still be some structural fatigue. The next time the toe cap comes under stress could result in serious injury.

If shoes are scuffed and worn around the toe area, with the steel toe cap visible, replacement safety footwear should be found. Once the toe cap is visible it will deteriorate more quickly and no longer protect the wearer as required.

Certain products protect better against steel toe scuffing, for example the Lincoln Waterproof Metatarsal Boot has a bump cap for extra protection and therefore a longer life.

According to the HSE, a third of all workplace accidents were slips and trips in 2019/20, meaning that the wear of the footwear’s tread is extremely important. If the tread on a slip resistant work boot shows signs of wear and damage, then it is likely that the footwear is reaching the end of its life. The more the tread is worn the less slip resistance it may have, making the wearer more susceptible to slip and trip hazards in the workplace.

Our new Tactical Footwear range, (which has a 4-star GRIP rating certified by UK government’s HSL), achieved a slip rating in excess of SRC after completing 1 million steps in a pedatron.

If an area on the shoe’s tread is worn smooth, then a replacement pair of slip resistant work boots should be found urgently. The visibility of a tread’s design represents a critical indicator for when footwear needs to be replaced.

In addition, should a sole be penetrated by a sharp object, water can enter inside the sole and corrode the midsole. In this eventuality the midsole will no longer be able to sustain the required amount of pressure to properly protect the user.

Cracking is a result of poor boot care. Cracking causes the structural integrity of the boot to be compromised and leaves it susceptible to hazardous liquids and solid objects entering inside the boot.

To avoid cracking, protective coatings can be applied to the leather upper as a preventative measure. If footwear is treated with polish or wax from the beginning it is less prone to splitting or cracking.

The leather upper will be prone to cracking where mud has been allowed to dry on the boot. Irritants such as mud and oil force moisture out of the leather which causes boots to crease. Creases lead to cracks especially around the flex points which are constantly worked when the wearer moves in the footwear.

In contrast, boots that have been soaked and not dried properly can cause the leather to shrink, warp or become limp. Once the toughness of the boot is undermined the question must be asked if the work boot can protect the user sufficiently.

For instructions on how to care for your boots to prevent cracking and water damage, refer to the Blackrock care guide inside your shoe box.

Shoelaces are exposed to the elements and will deteriorate more quickly than the leather upper. Once a shoelace becomes frayed or snaps, the laces should be replaced immediately.

Without properly lacing the boot the footwear will no longer fit correctly, resulting in accelerated wear, and is more likely to come away from the foot.

Due to the varying circumstances in which safety boots are used a definitive warranty can’t be given.

Whilst one pair of boots that are worn twice a week in a workshop may last a year, the same boots may last just two months when being worn all week on a construction site.

| 24 April 2024

Some simple and effective ways of checking your safety footwear is still fit for purpose.

READ POST

Editorial | 10 March 2021

Find out more about the newest additions to the Blackrock footwear range

READ POST

Editorial | 20 December 2021

Over the last year you may have seen the phrase ‘tactical footwear’ mentioned by us. But what is tactical footwear?

READ POST

| 06 June 2022

Work gloves shouldn’t be complicated. So what does PU, FN, LC etc mean?

READ POST

Editorial | 20 October 2021

We look at how the Tactical Footwear range stacks up against real world use by members of the police.

READ POST

| 23 January 2023

Footwear comfort is heavily affected by the type of protective midsole you have. Which is the best for you?

READ POST

| 17 August 2023

Here's a brief overview on the latest update of safety footwear standards.

READ POST

| 29 January 2024

Having appropriate and legitimate safety footwear is more important than ever.

READ POST

| 05 April 2023

We answer some of those questions you may have been faced with when having to choose safety footwear.

READ POST

| 25 July 2023

With safety trainers, having to sacrifice style for the sake of safety is no longer a requirement.

READ POST