ALL Gloves

| 12 May 2023

We look at some of the misconceptions surrounding cut resistant gloves and the correct way they should be used.

Do you want to get to the point – or more appropriately, protect yourself from it - when it comes to cut resistant gloves?

Your hands are so fundamental to everything you do – both at work and play – that protecting them whenever possible should be a primary motivator, particularly if you’re in the type of job where your digits are much more vulnerable than usual.

Below is an informative look at some of the misconceptions surrounding cut resistant gloves, the correct way they should be used and what’s available across the categories.

Principally, cut resistant gloves are a great piece of safety kit for those jobs in an industrial setting where the risk of hands receiving any kind of minor – or indeed major - lacerations are a potential daily possibility.

There are many different cut resistant gloves in our collection to suit a variety of working conditions, but we feel it prudent to offer a sensible - if somewhat obvious - word of caution. While chainmail will largely prevent direct content with a knife, there is no such thing as entirely cut-proof gloves.

That’s right. Owing to the flexible requirements of the cut resistant glove, the rigidity you’d need to make this piece of equipment pretty much impenetrable simply wouldn’t work for the functional and ergonomic demands of a glove in the workplace.

Cut resistant gloves are designed to help reduce the chances of being cut, and most importantly, significantly reduce the severity of any cuts you may accidently incur.

We all want to avoid any horrific injuries at work. While common sense should be engaged when attempting to handle any issues even the most robust safety gloves might struggle to prevent, sometimes hazards like shattered, protruding pieces of glass can be hidden from plain sight.

In such cases as this, wearing cut resistant gloves may be the difference between sustaining an unpleasant surface wound and potentially losing a finger or severing an artery.

Like the rest of our safety gloves, the cut resistant gloves follow a rigorous testing code, which is represented via different levels of cut resistance based on the hazards the worker may face.

That level of protection hinges on the type of material used in their manufacture – commonly a combination of stainless steel, glass and high-performance fibres, alongside elements like glove thickness and construction.

You may be asking yourself - just how much versatility does the average cut resistant glove offer for the wearer? The good news is that due to the development of anti-cut fibre technology over the last decade or so – and the increased importance placed on the health and safety of employees - cut-resistant gloves are now thinner, lighter and much more comfortable than previous incarnations.

Please bear in mind that those gloves which are designed at the highest level of cut-resistance will be, by their very nature, a little thicker and less dexterous.

Our own cut resistant glove range features eight different styles, each designed to offer protection whilst enhancing the wearer’s performance.

As with many products on the PPE market, machine washing isn’t really recommended. As far as these gloves are concerned, this washing method runs the risk of damaging the coating – be it latex or PU & nitrile – which could ultimately affect the level of grip the gloves give off, thus compromising their ability to perform to the Mechanical Hazard Ratings.

Chances are if you’re using cut resistant gloves, you’re in a role which isn’t going to leave them completely filth-encrusted after a week’s work. If they do require a little wipe, a quick rub down with a warm damp cloth should suffice.

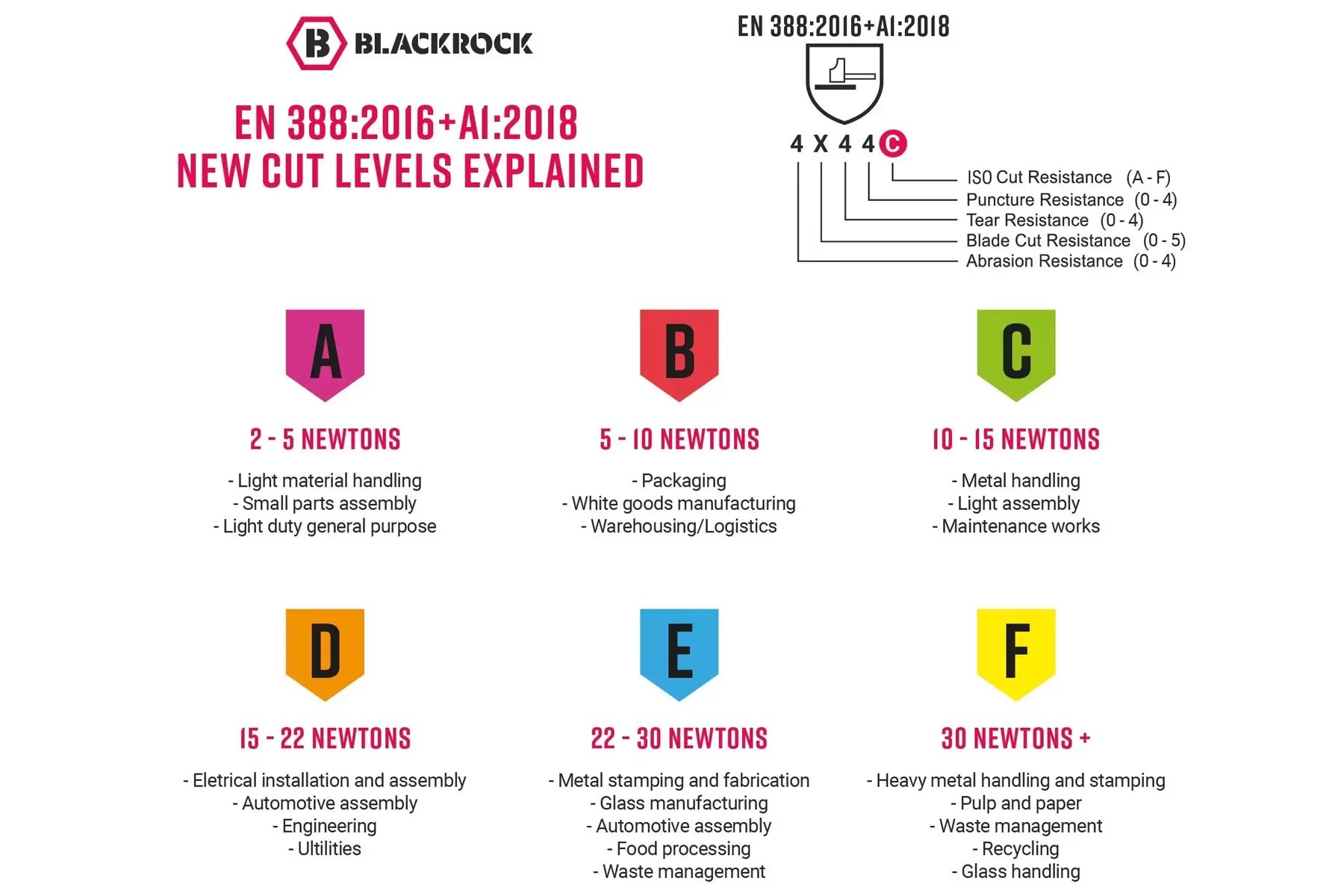

Gloves are tested under the European standard EN388:2016 Mechanical Protection. A required standard for protective gloves sold in the European Union and adapted into UK standards. This safety standard grades the level of protection when a specific set of mechanical hazard tests have been undertaken and passed.

In 2018 the testing method for cut-resistant gloves changed. And cut resistance went from numbers to letters. Our own cut-resistant glove range displays the new lettering system on the back of the glove which is where you’ll also find the mechanical hazard rating, alongside the ISO cut level protection rating for ease of selection. All of these can be seen below.

It’s worth noting that the new letter-based safety system isn’t parallel, safety-wise, with the previous numbered order. This is down to the difference during the testing process. The blade used to carry out the test is now changed after every successive test stroke to ensure a consistent sharpness is maintained, rather that the lessening of sharpness with every stroke of the same blade in the previous test.

Furthermore, it’s important to select the correct cut resistant gloves by taking into consideration the products, elements or materials that you will be handling.

While the EN standards should always be the first point of call when considering purchasing any kind of safety wear, there are always elements outside of this which factor into the decision-making process. Here at Blackrock we’ve tried to address this concisely and clearly through our Hex Ratings. This consists of a simple traffic light system for an easy, at-a-glance comparison between our gloves. Alongside the cut resistance level, you’ll find key properties like comfort, warmth, grip, dexterity and waterproof effectiveness, all helping to offer an informed decision for the customer.

While all this is undoubtedly informative and will point you in the right direction, there are still many other industries and appliances which bring operators into contact with the types of hazards the safety gloves are designed to mitigate serious injury, if an accident were to happen.

If you are looking for a little more advice, it’s always worthwhile to contact a member of our sales team who will be able to fill in those blanks for you and suggest which type of glove will work best for your needs.