ALL Gloves

Editorial | 12 May 2021

Guidance on choosing the right respirator for the job by identifying the workplace exposure limit.

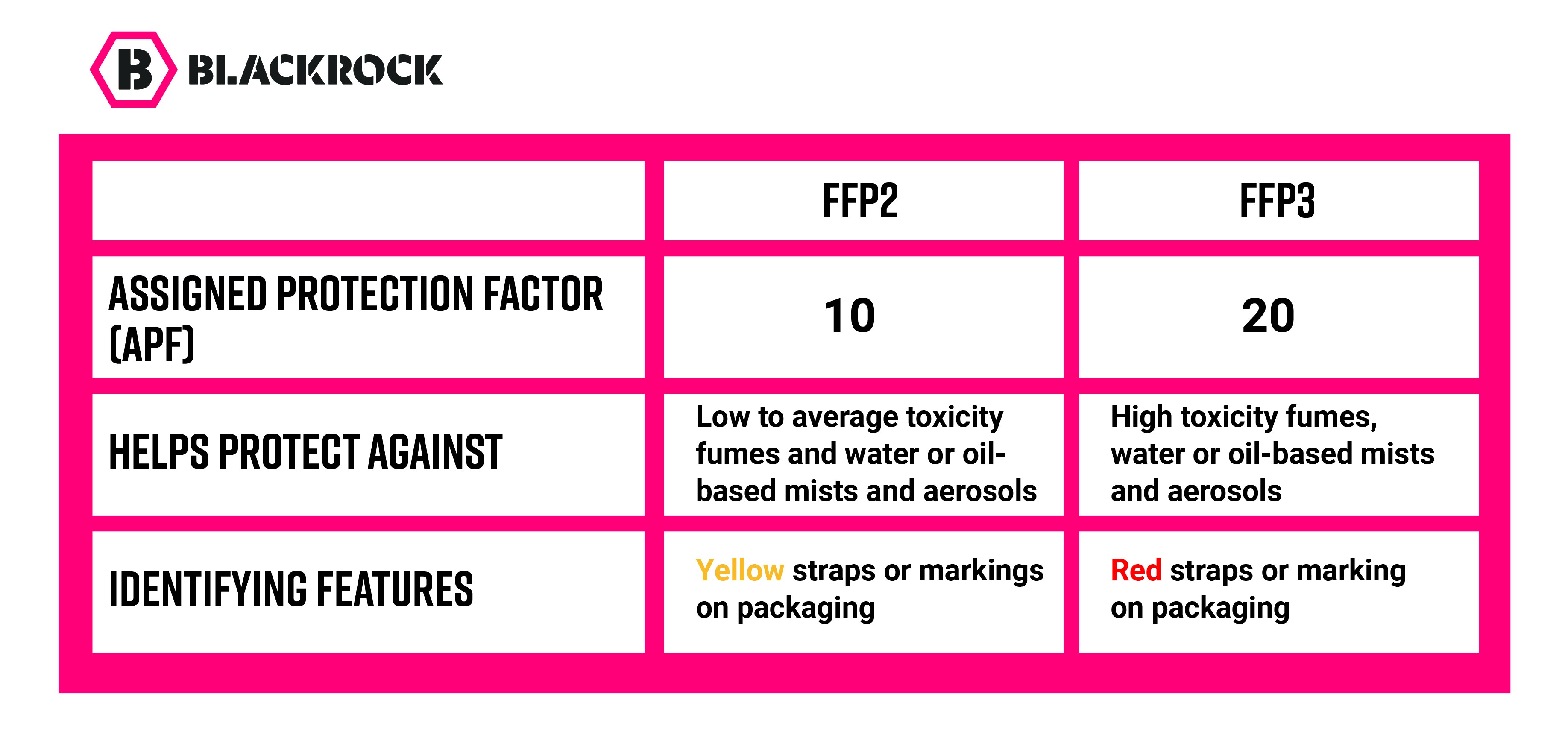

New Blackrock Eazi-Breathe respirators have an Assigned Protection Factor (APF) of 10 for FFP2 respirators and 20 for FFP3 respirators. But what does APF mean and why is it relevant?

The Assigned Protection factor is the level of respiratory protection that a respirator is expected to provide employees in the workplace.

An APF factor of 10 means that no more than one tenth of the contaminants to which a worker is exposed will leak into the mask.

There are five levels of APF: 4, 10, 20, 40 and 2000. The greater the number, the greater the level of protection.

Read more: When to use a Respirator

An RPE with an APF rating of 10 or more is designed to protect the wearer from dusts, fumes and vapours or gases that are larger than 2 microns. An RPE should be used in the following instances:

An APF rating of 20 will help protect the wearer against high toxicity fumes, water or oil-based mists and aerosols.

20 APF will also protect against concentrations of organic vapours, inorganic/acid gases and ammonia up to 20x Work Exposure Limit (WEL).

On the other hand, an APF rating of 10 will help protect against low to average toxicity fumes and water or oil-based mists and aerosols.

To determine which mask is required for your task a risk assessment should be carried out to determine the workplace exposure limit.

Thousands of substances are used in the workplace but only around 500 substances have Workplace Exposure Limits (WELs) listed in EH40 workplace exposure limits, (the environmental hygiene guidance note issued by the United Kingdom's Health and Safety Executive).

The work exposure limit (WEL) is what the Health and Safety Executive deems to be a safe amount of contact that a person can have with particular substances over a certain period.

A risk assessment is done to establish what the WEL will be whilst working with a hazardous substance. If the levels of concentration from the substance are under the WEL then no action needs to be taken. If the exposure limits are higher than the WEL then action should be taken to reduce exposure.

For example: if the substance(s) the employee is in contact with has 300ppm (parts per million), and the WEL has been assessed to be 50ppm for that substance, action is required to reduce the exposure to at least 50ppm.

By dividing the substance exposure by the WEL, we can work out the minimum APF required for the task.

300ppm/50ppm = 6

A minimum APF of 6 is required – therefore any of the masks that have an APF of 10 are adequate to mitigate the exposure.

Fold2Fit Eazi-Breathe FFP2 Respirator

Fold2Fit Eazi-Breathe FFP3 Respirator

Moulded Eazi-Breathe FFP2 Respirator

| 24 April 2024

Some simple and effective ways of checking your safety footwear is still fit for purpose.

READ POST

Editorial | 10 March 2021

Find out more about the newest additions to the Blackrock footwear range

READ POST

Editorial | 20 December 2021

Over the last year you may have seen the phrase ‘tactical footwear’ mentioned by us. But what is tactical footwear?

READ POST

| 06 June 2022

Work gloves shouldn’t be complicated. So what does PU, FN, LC etc mean?

READ POST

Editorial | 20 October 2021

We look at how the Tactical Footwear range stacks up against real world use by members of the police.

READ POST

| 23 January 2023

Footwear comfort is heavily affected by the type of protective midsole you have. Which is the best for you?

READ POST

| 17 August 2023

Here's a brief overview on the latest update of safety footwear standards.

READ POST

| 29 January 2024

Having appropriate and legitimate safety footwear is more important than ever.

READ POST

| 05 April 2023

We answer some of those questions you may have been faced with when having to choose safety footwear.

READ POST

| 25 July 2023

With safety trainers, having to sacrifice style for the sake of safety is no longer a requirement.

READ POST